Future-proof your cleaning with Kleen Power

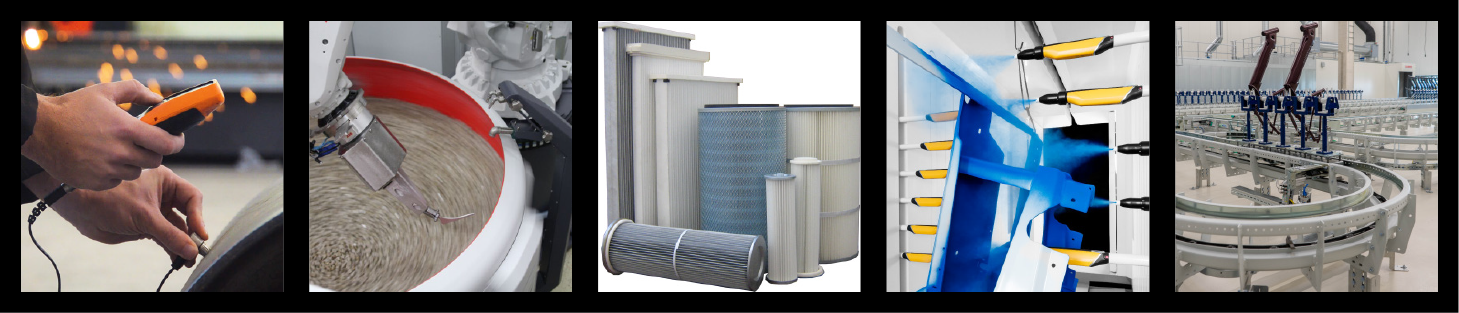

The systems use a mixture of spray, basket rotation, aqueous cleaning, modified alcohols hydrocarbons, hydrocarbons HFE and ultrasounds. The advantages of the machines are:

- Minimal loss of solution, substantially reducing the process cost and environmental affect.

- Distillation, separation, and filtration of contaminants allow the reuse of oils in machining processes and swarf/particles to be reused or economically disposed of.

- Uses modified alcohols with a flash point of over 60°C under vacuum, so machines don't need to be fabricated to ATEX-approved standards, reducing machine cost.

- Ethernet connection allows online diagnosis of technical problems and predictive maintenance.

- Cleans component areas that are difficult to reach (such as blind holes and tubes) with Aqueous / HFE solvents.

The ideal applications are advisable according to the quantities to be treated, the quantity of contamination, and the size of the semi-finished products. Kleen Power tech is appreciated in the fields of precision mechanics, medical, dental, automotive, heat treatment, moulded components, oleodynamic components, springs, jewellery, watches, and electronics.

As well as this new range of Vacuum Solvent cleaners, Kemet additionally provide;

- Ultrasonic Cleaning Tanks ranging from 40 to 160 litres with over 400 elevated performance formulations to pick from.

- Aqueous Cleaning Fluids with validation qualities of ISO 19227-2018 and biocompatibility qualities of ISO 10993-18, perfect for the Medical and Aerospace industries.

- Passivation lines that meet ISO 7 clean room.

Call Kemet on +44(0) 1622 755287 or email Sales@Kemet.co.uk to arrange cleaning trials, so Kemet can ascertain the perfect cleaning approach for you.