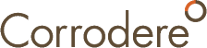

Jacquet Weston Engineering brings ‘energy chain’ cable management to installation design

“Every facility requires electrical cabling to enable the control and transportation systems to access the full length of the process tanks involved,” says Nick Weston, JWE’s Managing Director. “Conventionally, this has seen cable supply looped along the line with steel supporting racks and trolleys positioned at key points to accommodate loadings that can be significant. Now, with this latest development, not only can the need for this approach be eliminated in many cases, but other aspects of installation efficiency can also be enhanced.”

JWE is utilising the energy chain system from UK manufacturer igus which provides a highly versatile means of containing electrical distribution cable along the full length of a process line. A series of reinforced plastic sections are linked together to house the cable with the resultant lines simply extending and retracting to match positioning and processing needs along the full length of the tank layout.

“The result is a far tidier electrical supply distribution system and markedly simplified maintenance,” continues Nick Weston, “while the absence of looped cable also reflects each customer’s health and safety commitment.” He also points out that process line dimensions can benefit from the fact that no cable support system is required, particularly in terms of the overall height of a facility.

“We owe much of our success to a continuous commitment to product and process line development and this latest step forward is evidence of that approach,” continues Nick Weston. “The decision to opt for the igus system reflects not only on the functionality of the energy chain design but also the quality of the materials and linkage systems used – both of which highlight the challenges of many process line installation environments. This is an important step forward and one which we are sure will be acknowledged by every customer,” he concludes.